LabVIEW production line vision inspection system

THE CHALLENGE

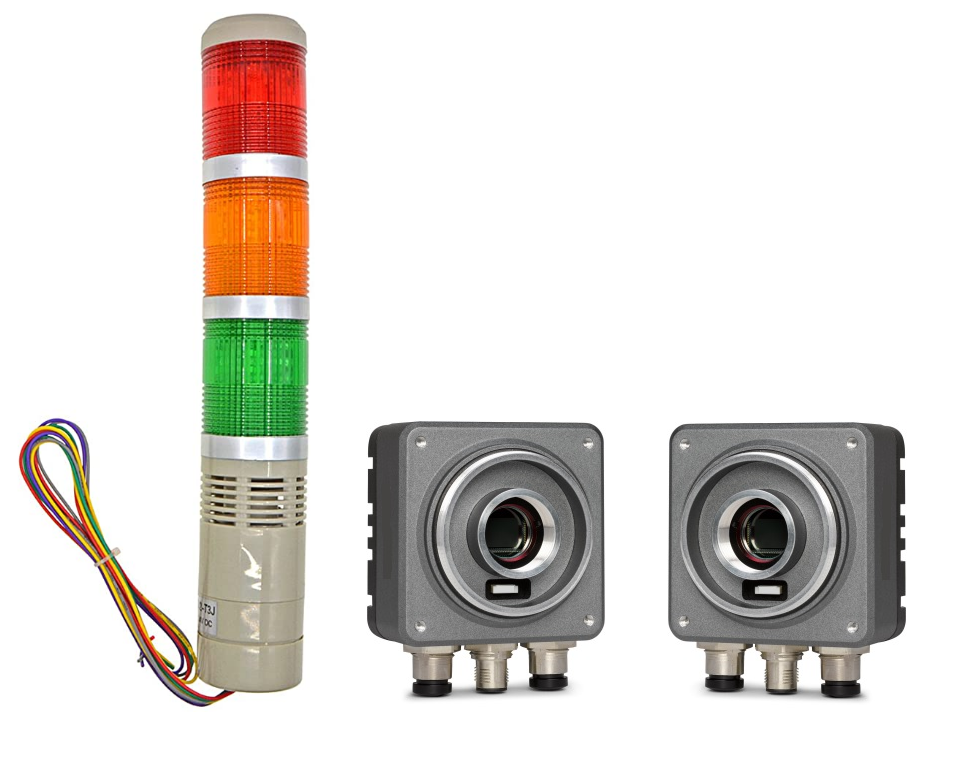

The client, a world leader in graphics, lighters, razors, and promotional products had a need to create an automated vision station to validate their product during the manufacturing process. The strategy was to use 2 NI (National Instruments) compatible vision cameras, an NI-16 bit DIO and the NI LabVIEW vision development platform to design and develop a test application that was capable to scan both sides of the UUT (unit under test) as it passed through the test station at high speeds during the manufacturing process. The ultimate goal was to stop any unsatisfactory units from leaving the factory.

THE SOLUTION

We designed and developed an NI LabVIEW vision-based, real time data acquisition software application system which would scan the UUT (unit under test) and detect all unsatisfactory units before they could leave the factory, as well as display a final test result (Green, Yellow and Red) after every test and save the test results. The client also provided an additional resource in the form of an external trigger that when received, the test station would capture and examine the current UUT. A series of visual test were performed on the captured images (testing 20 different points on each UUT) and a final test result was produced. Additionally, the test station would send a signal through one of the NI DIO output ports which would set the industrial signal light (Red Yellow Green) LED alarm tower indicator continuous lamp warning light with buzzer to the resulting color.

There were three (3) possible results, Pass, Warning and Fail.

If the NI vision test system produced a result of Pass, no action would be taken and the alarm tower indicator lamp warning light would remain at the default color Green.

If the NI vision test system produced a result of Warning, a test operator will examine the captured images (displayed on screen) to determine what correction was to be applied without stopping the production process. Additionally, a signal would be sent through the NI DIO output ports which would set the alarm tower indicator lamp warning light to Yellow. Once the corrections were applied, the test station would be reset and testing of the production units would continue.

If the NI vision test system produced a result of Fail, the test system would then stop the production process, which would allow for the test operator to examine the test results and make the necessary corrections, reset the test station and then restart the entire production line process. Additionally, a signal would be sent through the NI DIO output ports which would set the alarm tower indicator lamp warning light to Red.

We provided the client with a final executable file and an application installer so the test station could be easily duplicated. The application was executed using the FREE NI LabVIEW Runtime engine but additionally required the NI Vision Runtime Engine which came with additional licensing costs per each installed test station.

This new test station allows our client to automatically test their production units, performing tasks at speeds that no human could perform. In one footprint in a corner of the production area, this test station can keep up with the growing production quantity. Furthermore, this test station was developed as so additional devices for test could be easily added to the test station software with minimal software development and effort.

LabVIEW production line vision inspection system

THE CHALLENGE

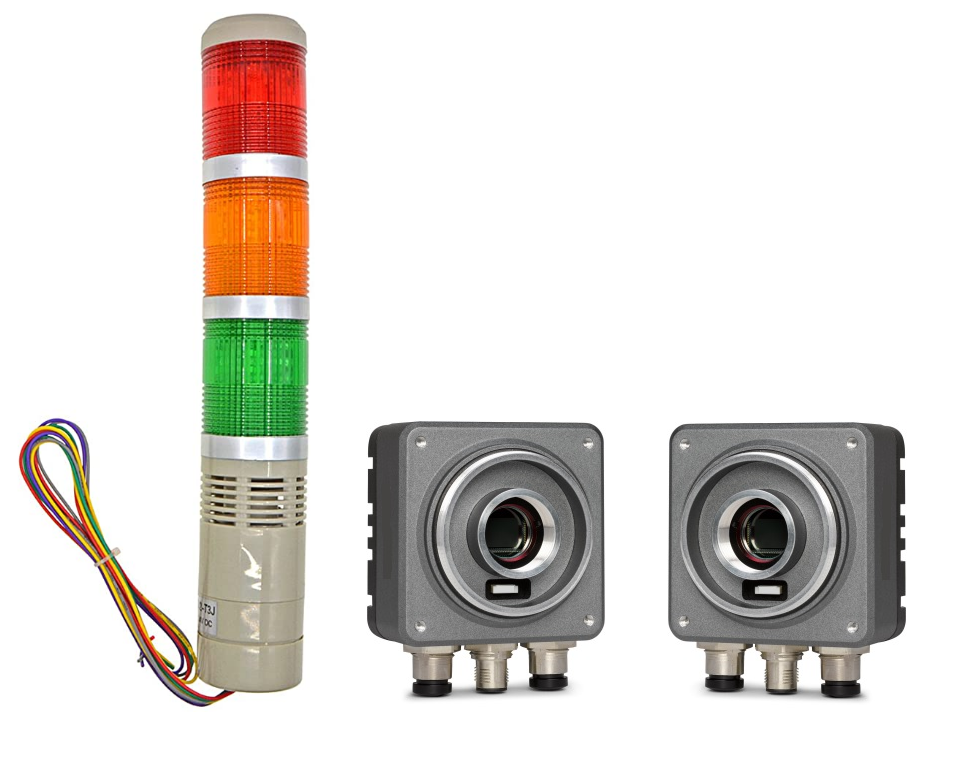

The client, a world leader in graphics, lighters, razors, and promotional products had a need to create an automated vision station to validate their product during the manufacturing process. The strategy was to use 2 NI (National Instruments) compatible vision cameras, an NI-16 bit DIO and the NI LabVIEW vision development platform to design and develop a test application that was capable to scan both sides of the UUT (unit under test) as it passed through the test station at high speeds during the manufacturing process. The ultimate goal was to stop any unsatisfactory units from leaving the factory.

THE SOLUTION

We designed and developed an NI LabVIEW vision-based, real time data acquisition software application system which would scan the UUT (unit under test) and detect all unsatisfactory units before they could leave the factory, as well as display a final test result (Green, Yellow and Red) after every test and save the test results. The client also provided an additional resource in the form of an external trigger that when received, the test station would capture and examine the current UUT. A series of visual test were performed on the captured images (testing 20 different points on each UUT) and a final test result was produced. Additionally, the test station would send a signal through one of the NI DIO output ports which would set the industrial signal light (Red Yellow Green) LED alarm tower indicator continuous lamp warning light with buzzer to the resulting color.

There were three (3) possible results, Pass, Warning and Fail.

If the NI vision test system produced a result of Pass, no action would be taken and the alarm tower indicator lamp warning light would remain at the default color Green.

If the NI vision test system produced a result of Warning, a test operator will examine the captured images (displayed on screen) to determine what correction was to be applied without stopping the production process. Additionally, a signal would be sent through the NI DIO output ports which would set the alarm tower indicator lamp warning light to Yellow. Once the corrections were applied, the test station would be reset and testing of the production units would continue.

If the NI vision test system produced a result of Fail, the test system would then stop the production process, which would allow for the test operator to examine the test results and make the necessary corrections, reset the test station and then restart the entire production line process. Additionally, a signal would be sent through the NI DIO output ports which would set the alarm tower indicator lamp warning light to Red.

We provided the client with a final executable file and an application installer so the test station could be easily duplicated. The application was executed using the FREE NI LabVIEW Runtime engine but additionally required the NI Vision Runtime Engine which came with additional licensing costs per each installed test station.

This new test station allows our client to automatically test their production units, performing tasks at speeds that no human could perform. In one footprint in a corner of the production area, this test station can keep up with the growing production quantity. Furthermore, this test station was developed as so additional devices for test could be easily added to the test station software with minimal software development and effort.