US Military Power Management Systems test station

THE CHALLENGE

The client, providing solutions for the evolving needs of the modern soldier had a need to design and develop a new automated test station for a new mobile power system, a device used to scavenge and deliver power to and from multiple sources simultaneously. The client specifically requested the automated software test application to be designed and developed with the Microsoft Visual Studio C# and CAN Bus / J1939 messaging. Once the project was completed and the system was fully functional, decided to change the test station development language to PYTHON to make use of the existing and supported Python Can Bus functionality.

THE SOLUTION

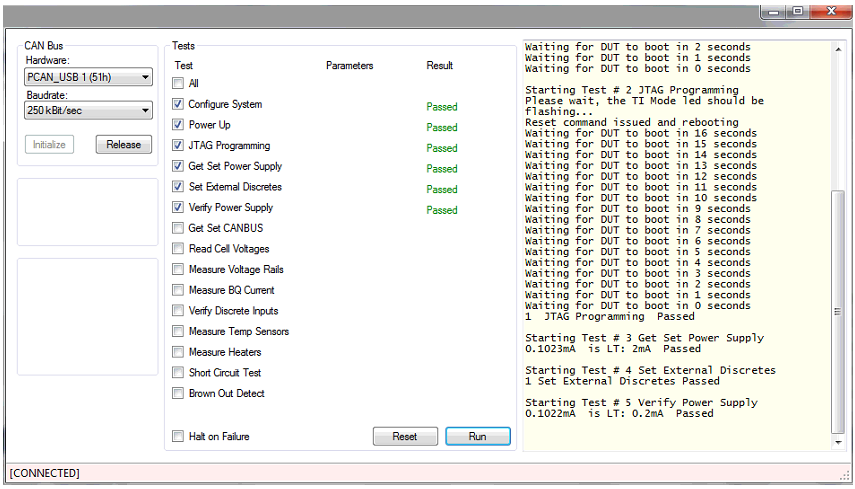

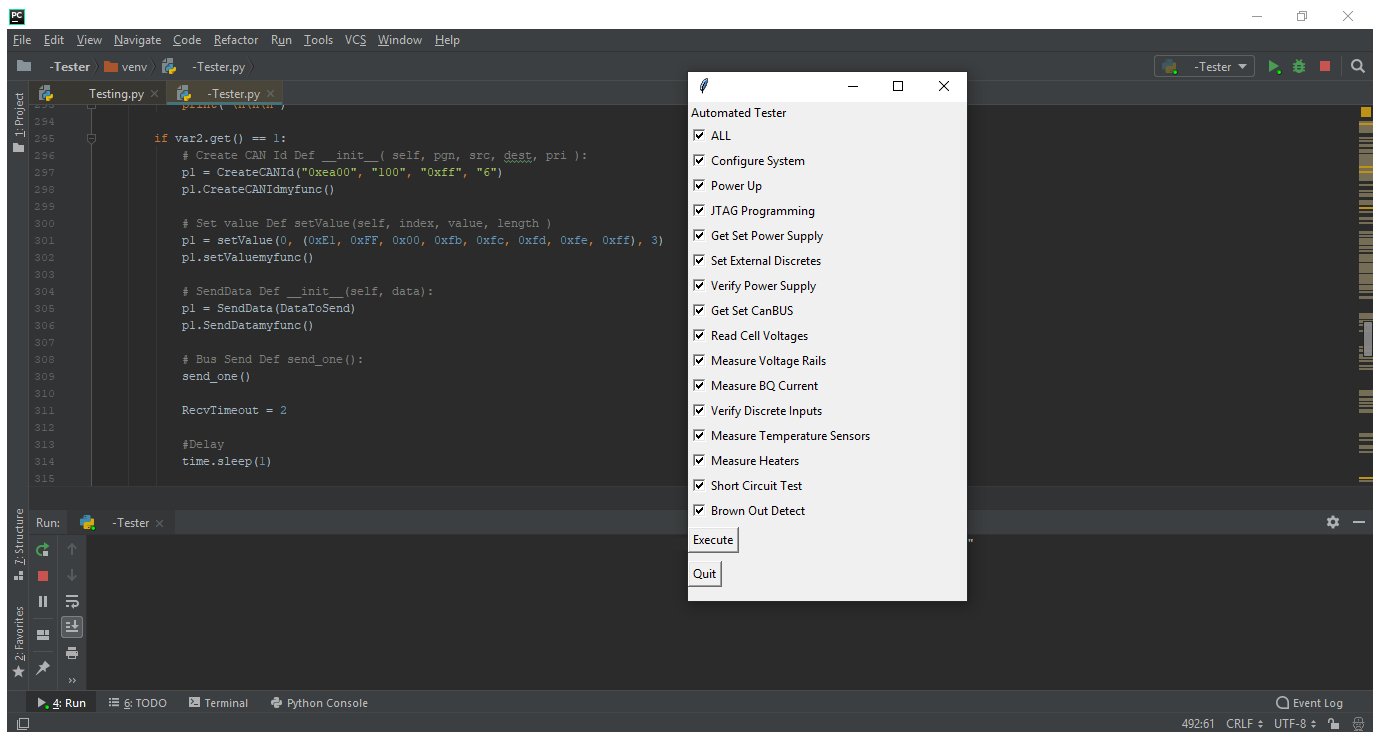

We designed and developed a test station to interface and communicate directly with the test stations power supply and the device firmware controller. We implemented CANBus communication, powered up and configured the UUT (unit under test), get and set power supplies settings, program the firmware, set external discretes, verify power supplies, get and set the CANBus, read cell voltages, measure voltage rails, measure current, verify discrete inputs, measure temperature sensors, measure heater sense and short circuit tests.

The test application would guide the test operator to make the required connections before each test. Once all the elements have been tested, the test process is then considered complete. The measured data and a pass-fail result are displayed on screen.

The test operator then has the option save a copy of the test report and print it to accompany the device under test. If the unit has failed, depending on the test, we programmed the test station with enough intelligence to indicate which components need to be verified and or replaced.

US Military Power Management Systems test station

THE CHALLENGE

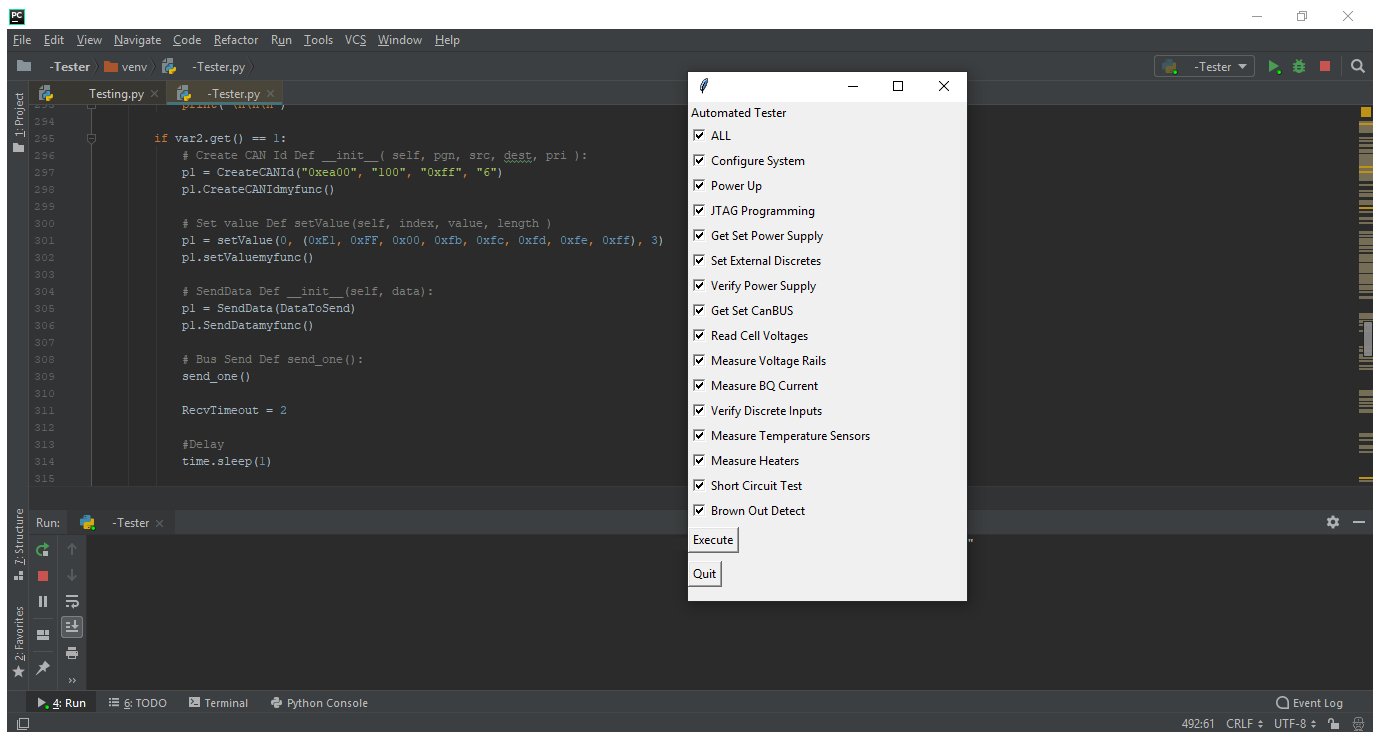

The client, providing solutions for the evolving needs of the modern soldier had a need to design and develop a new automated test station for a new mobile power system, a device used to scavenge and deliver power to and from multiple sources simultaneously. The client specifically requested the automated software test application to be designed and developed with the Microsoft Visual Studio C# and CAN Bus / J1939 messaging. Once the project was completed and the system was fully functional, decided to change the test station development language to PYTHON to make use of the existing and supported Python Can Bus functionality.

THE SOLUTION

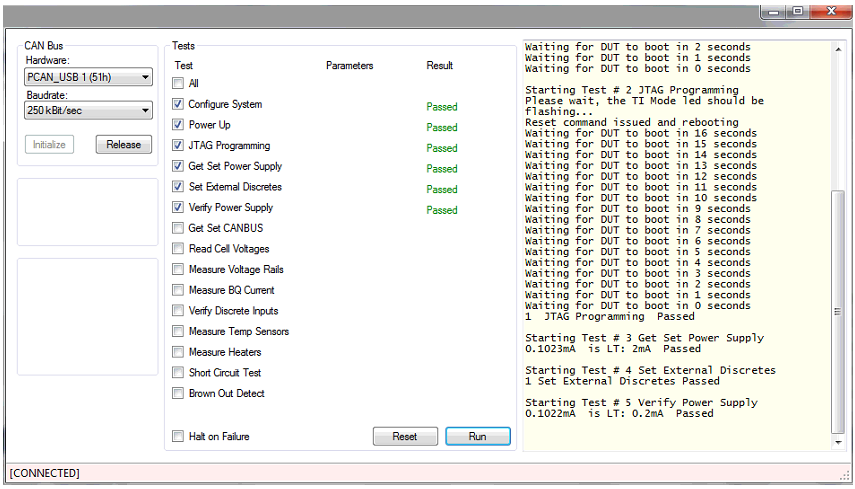

We designed and developed a test station to interface and communicate directly with the test stations power supply and the device firmware controller. We implemented CANBus communication, powered up and configured the UUT (unit under test), get and set power supplies settings, program the firmware, set external discretes, verify power supplies, get and set the CANBus, read cell voltages, measure voltage rails, measure current, verify discrete inputs, measure temperature sensors, measure heater sense and short circuit tests.

The test application would guide the test operator to make the required connections before each test. Once all the elements have been tested, the test process is then considered complete. The measured data and a pass-fail result are displayed on screen.

The test operator then has the option save a copy of the test report and print it to accompany the device under test. If the unit has failed, depending on the test, we programmed the test station with enough intelligence to indicate which components need to be verified and or replaced.