Helicopter main rotor damper automated test station for the A119 Koala, A109E Power and the AW139 helicopters

THE CHALLENGE

The client, a leading international provider of solutions for aircraft systems and services in the helicopter and general aviation markets had a need to automate their existing manual main rotor head damper test station for the AW139 helicopters, the A119 Koala helicopters, and the A109E Power helicopters. The challenge was that the new automated test application was to work in conjunction with the existing manual control system as well as all the hydraulic jacks and load monitoring devices in order to produce a standardized acceptance test report (for both civil and military standards) that could accompany the device under test through to its final installation stage.

THE SOLUTION

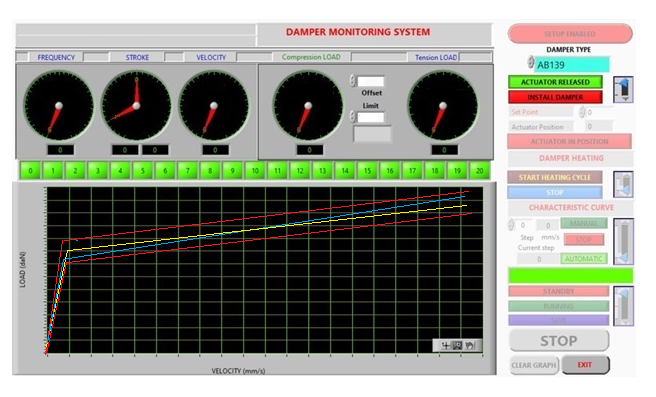

We designed and developed an NI (National Instruments) LabVIEW based, real-time control and data acquisition system software application to automate the main rotor damper test station. This new software application interfaced to the test station using the connections of the pre-existing devices and allowed for communication with the test computer. We could now fully control the test station devices and provided the required automation to acquire measurements, calculate, display, save and print the final test results.

The test operator could now select between one (1) of three (3) main rotor damper head models to be tested according to their own precise limits and specifications. We worked collaboratively with our client to design this automated test station with the main function to obtain and display the characteristic curve load / speed as defined in the ATP (automated testing procedure) to produce the appropriate acceptance test report.

The test operator is now guided through the various test step procedures with an easy-to-use UI. Where through the use of on-screen images, instructions and messages, the automated testing process assures the user had made the required connections and then begins to correctly test and produce a standardized acceptance test report (for both industry and military standards) that will accompany the device under test through to its final installation stage.

During this procedure, the test operator is prompted to input required data and when executed, the automated testing process would incrementally increase the frequency to the hydraulic jacks while recording and displaying real time measurements such as frequency, piston stroke, velocity, compression and tension loads at each step of the testing process. A final plot of the load velocity characteristic curve and a pass/fail result was displayed on screen to the test operator. Once all the elements had been tested and the process was complete, the measured data and a pass-fail result were visually displayed on the screen. The test operator then had the option save and print a copy of the test report which would accompany the device under test through the various production stages.

The automated test application also included a manual mode where the test operator could select a specific frequency for the hydraulic jack and execute a test and or control any or all of the devices of the test station during the manufacturing, repair and rebuild processes for the main rotor dampers.

Finally, we provided the client with the full NI LabVIEW source code for the automated test application, an automated test application installer (executable), the technical schematics and the bill of materials for the new interface so their in-house engineers could modify, repair or duplicate the test station.

Additionally, this new automated test application runs on the free NI LabVIEW runtime engine, so no additional NI LabVIEW licenses are required for any additional duplicate stations.

This new test station allows our client to test the main rotor head dampers both automatically and manually. Whether for production acceptance or rebuilds and repairs, this one automated test station can now test them all. In one small footprint in a corner of the production area, this test station can keep up with the growing production quantity. Furthermore, this test station was developed as so additional devices for test could be easily added to the test station software with minimal software development and effort.

Our clients have reduced their software development and maintenance costs by developing this control / data acquisition and load monitoring system with a single software environment, NI LabVIEW.

Helicopter main rotor damper automated test station for the A119 Koala, A109E Power and the AW139 helicopters

THE CHALLENGE

The client, a leading international provider of solutions for aircraft systems and services in the helicopter and general aviation markets had a need to automate their existing manual main rotor head damper test station for the AW139 helicopters, the A119 Koala helicopters, and the A109E Power helicopters. The challenge was that the new automated test application was to work in conjunction with the existing manual control system as well as all the hydraulic jacks and load monitoring devices in order to produce a standardized acceptance test report (for both civil and military standards) that could accompany the device under test through to its final installation stage.

THE SOLUTION

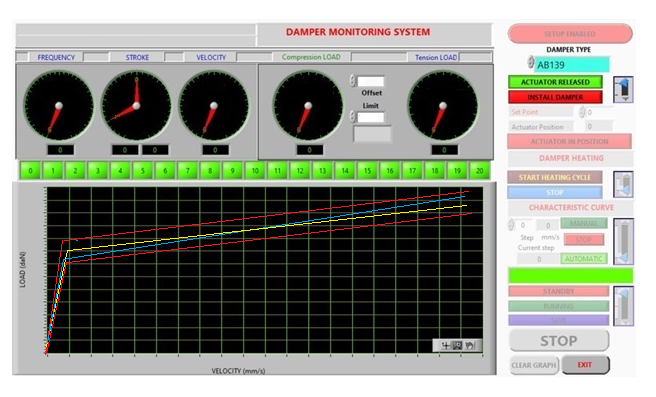

We designed and developed an NI (National Instruments) LabVIEW based, real-time control and data acquisition system software application to automate the main rotor damper test station. This new software application interfaced to the test station using the connections of the pre-existing devices and allowed for communication with the test computer. We could now fully control the test station devices and provided the required automation to acquire measurements, calculate, display, save and print the final test results.

The test operator could now select between one (1) of three (3) main rotor damper head models to be tested according to their own precise limits and specifications. We worked collaboratively with our client to design this automated test station with the main function to obtain and display the characteristic curve load / speed as defined in the ATP (automated testing procedure) to produce the appropriate acceptance test report.

The test operator is now guided through the various test step procedures with an easy-to-use UI. Where through the use of on-screen images, instructions and messages, the automated testing process assures the user had made the required connections and then begins to correctly test and produce a standardized acceptance test report (for both industry and military standards) that will accompany the device under test through to its final installation stage.

During this procedure, the test operator is prompted to input required data and when executed, the automated testing process would incrementally increase the frequency to the hydraulic jacks while recording and displaying real time measurements such as frequency, piston stroke, velocity, compression and tension loads at each step of the testing process. A final plot of the load velocity characteristic curve and a pass/fail result was displayed on screen to the test operator. Once all the elements had been tested and the process was complete, the measured data and a pass-fail result were visually displayed on the screen. The test operator then had the option save and print a copy of the test report which would accompany the device under test through the various production stages.

The automated test application also included a manual mode where the test operator could select a specific frequency for the hydraulic jack and execute a test and or control any or all of the devices of the test station during the manufacturing, repair and rebuild processes for the main rotor dampers.

Finally, we provided the client with the full NI LabVIEW source code for the automated test application, an automated test application installer (executable), the technical schematics and the bill of materials for the new interface so their in-house engineers could modify, repair or duplicate the test station.

Additionally, this new automated test application runs on the free NI LabVIEW runtime engine, so no additional NI LabVIEW licenses are required for any additional duplicate stations.

This new test station allows our client to test the main rotor head dampers both automatically and manually. Whether for production acceptance or rebuilds and repairs, this one automated test station can now test them all. In one small footprint in a corner of the production area, this test station can keep up with the growing production quantity. Furthermore, this test station was developed as so additional devices for test could be easily added to the test station software with minimal software development and effort.

Our clients have reduced their software development and maintenance costs by developing this control / data acquisition and load monitoring system with a single software environment, NI LabVIEW.